Blog PostA practical guide to the best printing techniques for your packaging

- Design

- Technology

- Innovation

Kris MooreMay 20, 2022 - 7 min read

Custom printed packaging is an important marketing strategy for any business. It’s used to create brand recognition and brand recall, to share important product information and it can make for a memorable customer experience. And what allows businesses to create this packaging, is access to a variety of printing techniques that can deliver.

At Sourceful, we work directly with manufacturers to supply businesses with the best packaging solutions and to ensure a high standard offering. And this includes giving customers access to high-quality printing techniques online in our Shop, including those usually only available offline.

Here’s a guide to our different printing techniques.

Flexographic printing

Flexographic printing, also known as flexo, is a versatile printing process used to print on plastic, paper, corrugated material and more. It involves using flexible printing plates that are wrapped around rolling cylinders. These plates are customised with your chosen artwork and rotated at high speeds to directly transfer ink to your packaging.

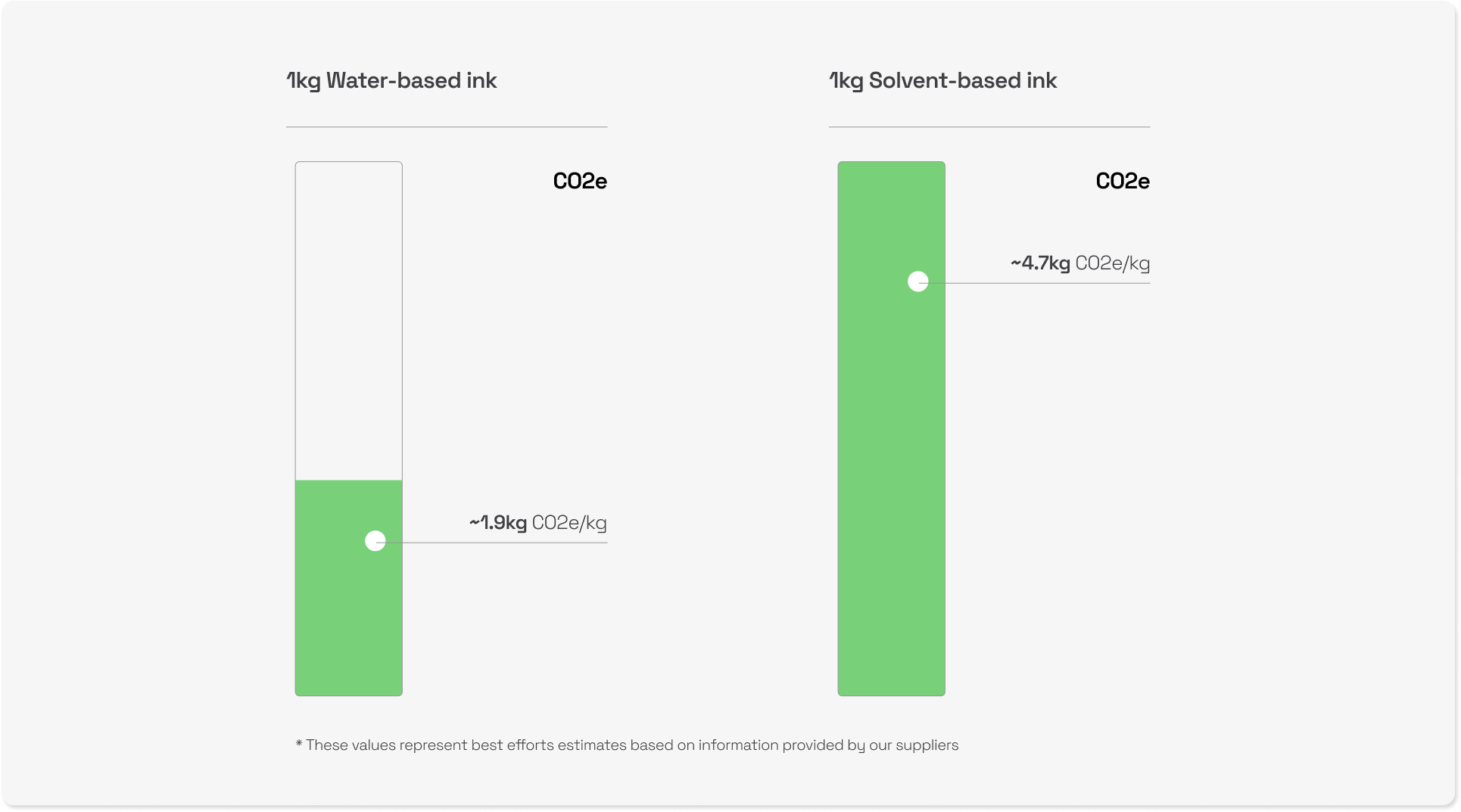

Both solvent-based inks and water-based inks can be used in flexography, though the latter is more popular due to its non-toxicity. The carbon footprint of solvent-based inks is on average 130-150% higher than water-based inks*. As the printing plates are slightly raised, flexography is often referred to as a modern-day letterpress.

Typically available as an offline request, we’ve worked with suppliers to bring flexographic printing online. We offer flexo for products like gummed tape, self-adhesive tape and shipping boxes in our Shop, as these tend to have simple, bold designs. The result is a product with a high-quality print and strong ink coverage.

Key benefits:

- Most economical and cost-effective option for high-volume print runs.

- Can be used on almost any flexible material, coated and uncoated, such as gummed tape, mailer bags and clothing pouch bags.

- Ideal for printing bold, straightforward designs or simpler graphics and text.

- Best suited for designs using 1-3 colours.

- Colours can be matched to Pantone and GCMI colours.

- Uses fast-drying inks, which means a fast production time and it’s safe for food packaging.

- Higher-order quantities can drastically reduce the impact of the printing on a per-unit basis. This is because the impact of the plate and the setup waste are fixed regardless of the order size.

Drawbacks:

- Flexo printing plates are made from photopolymer, the majority of which require setup and washing processes that utilise high impact solvents. These plates can affect up to 60% of the total impact of flexographic printing when produced through solvent-based processing.

- Each colour requires its own printing plate, so multi-colour designs are more expensive and have a higher carbon footprint.

- Large-sized products will have a higher impact as these require larger flexo printing plates.

- More intricate designs and finer details can lose resolution in print, especially on materials with high absorption such as uncoated paper.

By comparing the ink specifications from our suppliers we found that on average, 1 kilo of solvent-based ink has a 130-150% higher carbon footprint than 1 kilo of water-based inks.

Offset lithography printing

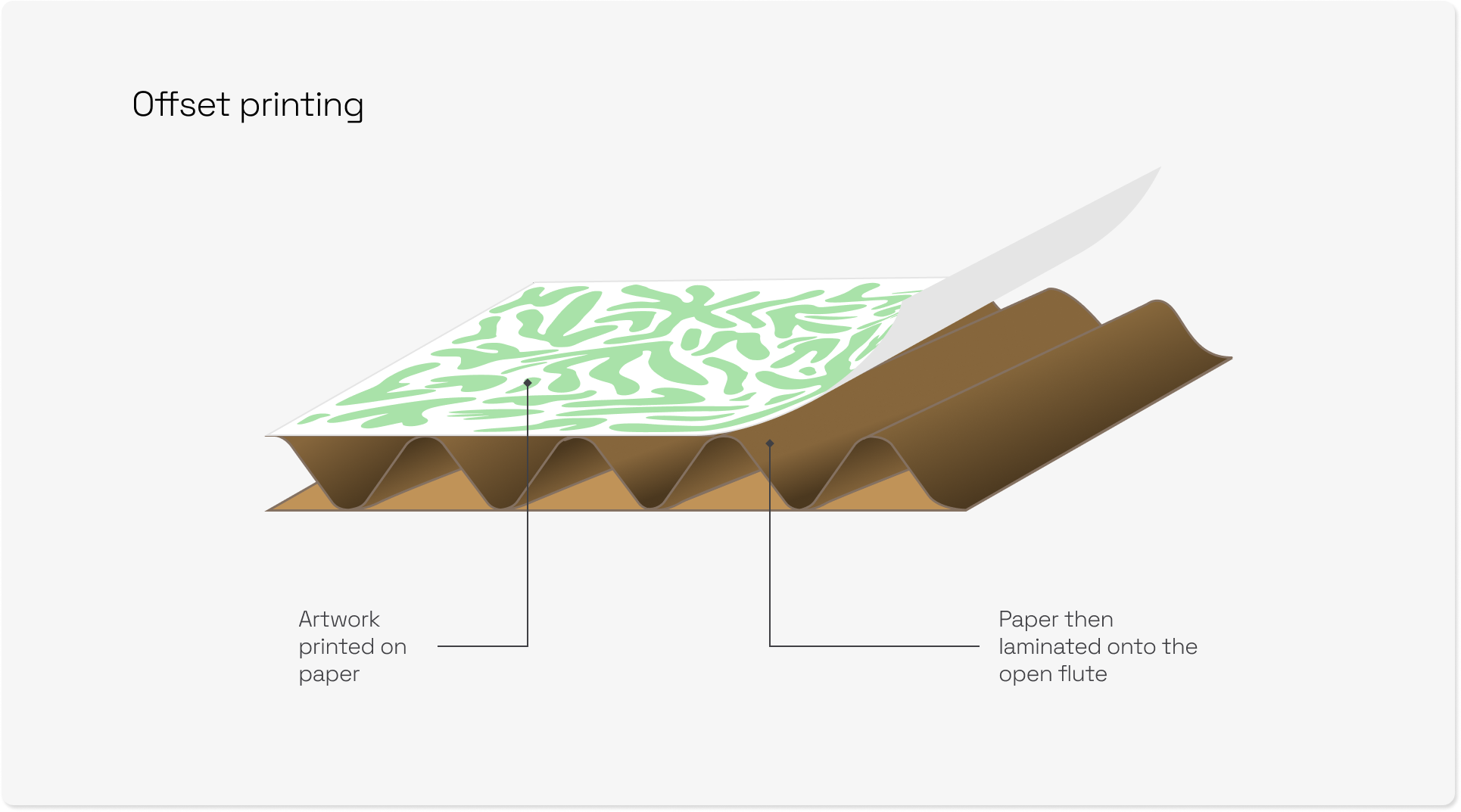

Offset lithographic printing, also known as offset printing, is the standard method used for high-volume, high-quality printing. It involves transferring your artwork from a computer onto an aluminium printing plate using a laser, which results in a high-quality print due to the laser’s precision.

It’s known as offset print because your artwork is not transferred directly from the printing plate to your packaging, but to an in-between rubber “blanket” surface first. Whilst offset printing is a versatile process, it’s unable to print on corrugated board as the material is too thick for the printing press. So for a product like a mailer box, the design is instead printed onto a sheet of paper which is then laminated onto the board. This results in a high-quality print finish for your artwork and allows the structure and fluting of your box to remain intact as it hasn’t been pushed through the press. It also means that more print finish options, such as a UV varnish finish, are available for your mailer box.

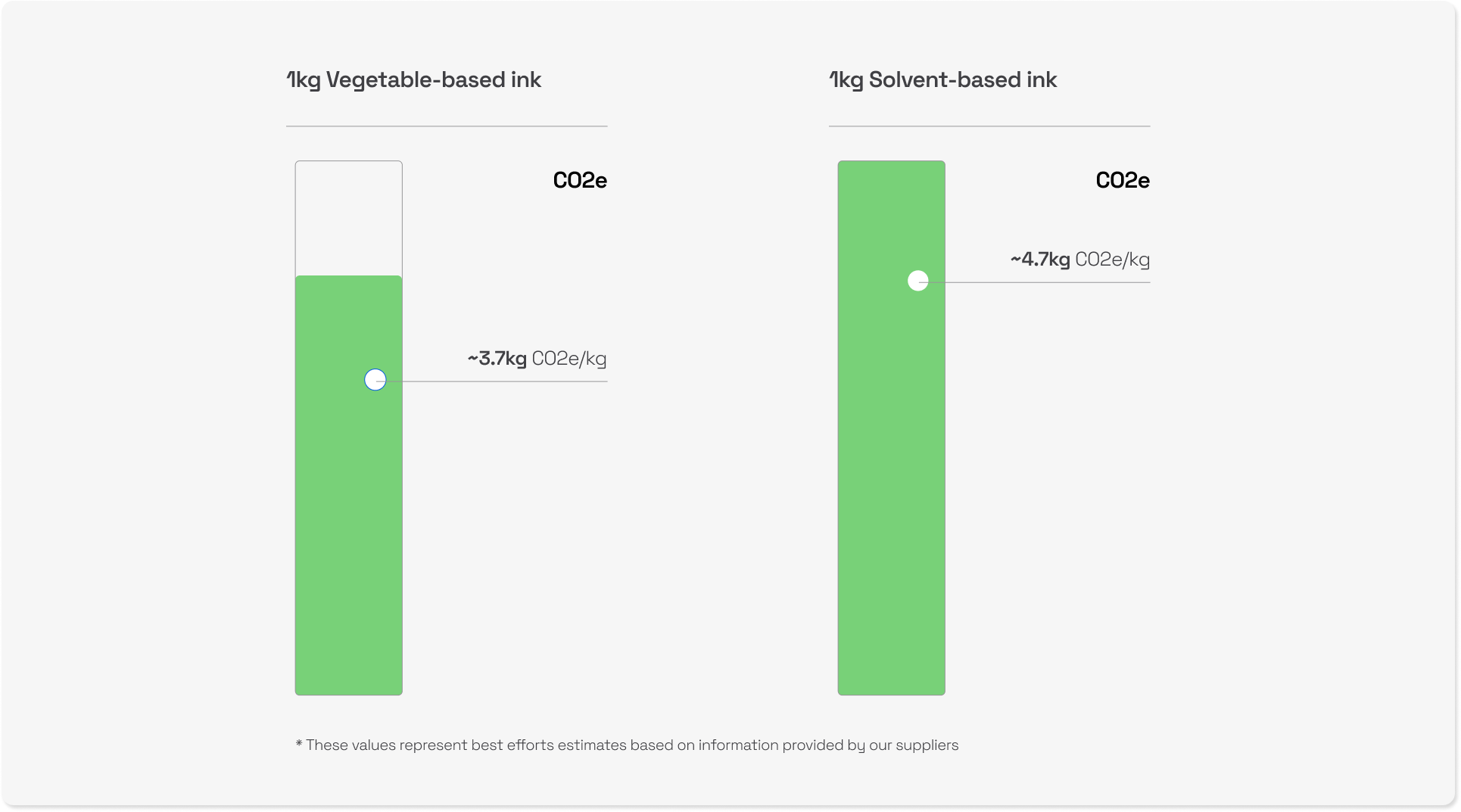

We offer offset printing for mailer boxes so that your artwork can be as intricate and detailed as desired, without compromising on print quality. To help lower emissions, we use vegetable oil-based inks for offset printing at Sourceful. The carbon footprint of these inks is on average 20-30% lower than solvent-based inks*.

Key benefits:

- Cost-effective when used for high volume print runs.

- Can be used on flexible materials, such as paper, box dividers, carton board.

- Ideal for complex designs, gradients, bright colours, smaller text and photography.

- Multiple single colours and full colour CMYK printing options.

- Colours can be matched to Pantone and GCMI colours.

- Available with a variety of finishes such as gloss or spot varnishes.

Drawbacks:

- Can only be used on flexible, thinner materials, like paper and paperboard.

- Only available with oil-based inks. Most of these are solvent-based and have high levels of volatile organic compound (VOC) emissions. At Sourceful, however, we use vegetable-based oil inks.

- Complex set-up, which means costs are higher for small volumes and MOQs are higher.

- More waste is produced during set-up. A manufacturer needs to run a certain number of units through the machine before the print quality reaches the right standard. This increases with the number of colours. For a one-colour, single-side print job, on average, 80 sheets are wasted for offset printing, whilst for flexo, the number of units wasted drops to 35**.

By comparing the ink specifications from our suppliers we found that on average, 1 kilo of solvent-based ink has a 20-30% higher carbon footprint than 1 kilo of vegetable-based inks.

The waste to set up offset printers represents between 7-60% (depending on the process and box size) of the total impact for a MOQ of 500 units. Whereas for flexo printers, the set up waste represents 4% of the total impact for a MOQ of 1000 units.

Digital printing

Digital printing is one of the most accessible printing options online. It’s a direct printing process, which uses digital laser or ink-jet printers to print directly onto your packaging. As there’s no mechanical setup needed, digital printing is a cost-effective option for small print runs. It also prints in full colour (CMYK), giving you maximum flexibility with your artwork designs. And because it’s all digital, you can easily make last-minute artwork changes.

Whilst digital printing allows you to create high-quality and photorealistic designs, you are likely to find small imperfections. For example, colours may be slightly off or the lining of your artwork may be less refined. And depending on the material used, the ink may be absorbed resulting in more muted colours. For this reason, digital printing works best for lower volume prints, such as stickers, and with designs that keep these potential imperfections in mind.

Key benefits:

- Cost-effective process used for small and large print runs.

- Ideal for vibrant, multi-coloured designs and photorealistic images.

- Full-colour printing available at no extra cost.

- Pantone and GCMI colours can be replicated in CMYK.

- Artwork can easily be amended.

- No printing set-up cost, which means a reduced cost for small volumes.

Drawbacks:

- Colours not exactly matched to Pantone and GCMI colours.

- Print quality can vary depending on the equipment and the material printed on.

- Less significant cost savings for higher volumes compared to flexographic and offset printing.

High-quality printing online with Sourceful

Each printing process suits different design requirements. Flexographic printing is great for transit packaging like shipping boxes that use simple, bold designs. Digital printing allows you to print smaller volumes of packaging, quickly. And offset printing is the best choice for packaging that requires detailed, high-quality printing.

If you want to keep your carbon footprint low, flexographic printing performs best for lower volumes of smaller products. And offset printing performs better for larger-sized products*.

At Sourceful, we understand each business has different packaging requirements which is why we’ve made each of these high-quality printing techniques available online.

We’ve worked with suppliers to support them in bringing these techniques online. This involved building dynamic pricing formulae – allowing us to price your packaging at the point of sale. We’re the first platform to provide dynamic pricing, live visuals and custom sizing for flexo and offset printed packaging. And this allows us to present costs that we can commit to immediately, without going back and forth on plate fees, print costs and more. Get started today.

When comparing our offset printed mailer box with our flexo printed shipping box, the data showed that at lower volumes for smaller boxes, flexo performs better than offset, given the high printer setup waste. However when you increase the size of the box, offset starts to look more favourable.