Blog PostIntroducing Spring: the new AI tool from Sourceful

- News

Wing ChanAugust 1, 2023 - 2 min read

Update: Spring is now Sourceful. As on May 2025, Spring by Sourceful became Sourceful and is available to all on www.sourceful.com.

We're thrilled to finally announce the launch of Spring; our first cutting-edge AI tool that empowers brands to break free from creative block and generate unique packaging inspiration in minutes. All with zero effort — and for free.

Stay ahead of the competition

Today, brands are under more pressure than ever to create and produce faster — and that includes their packaging. But more often than not, brands can't simply scale their resources to meet this demand. In other words, there's now more work to be done in less time with the same number of people.

We created Spring to fix this problem. Now, instead of relying on expensive external packaging designers to ease the load, you can generate packaging inspiration yourself in minutes and for free. In turn, you can move faster, launch quicker and stay competitive.

How Spring works

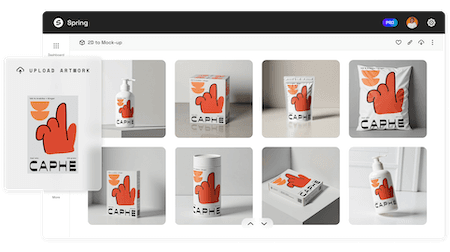

Spring uses generative AI to produce unique packaging ideas based on your inputs, all in a few minutes. Put another way, it's like having an entire team of packaging designers at your fingertips, ready to shower you with inspiration whenever you need it. And it couldn't be easier to use:

- Go to spring.sourceful.com

- Fill in the short form about your brand, product and needs

- Click Submit

That's it — we promise. Spring will generate nine unique packaging design ideas and send you them by email.

Turn your ideas into reality

Spring is incredibly powerful, but it's not meant to deliver final ideas, proofed artwork or structural designs. That's what a packaging partner — like Sourceful — is for. Here's how to turn your packaging inspiration from Spring into reality:

- Click Book your FREE consultation to connect with a Sourceful Account Manager. We'll then help you turn your idea into a reality.

- Recreate your ideas in Sourceful Studio — our online packaging design studio.

- Take your new ideas as a ready-made mood board to an external packaging designer.

Whichever way, with Spring you've just leap-frogged the hardest part of the creative process: the blank page.

Ready to be inspired? Discover Spring