Fully customisable

FSC certified

Custom sizing

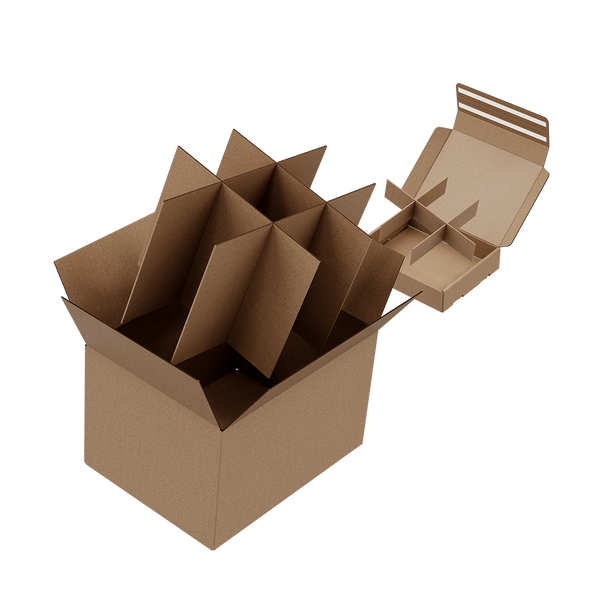

Cardboard Box Dividers

Minimum order quantity: 1000

Corrugated box dividers are a simple, cost-effective way to prevent products from moving in transit and separate components. Choose the exact dimensions to fit your box with custom sizing. Pair with a Sourceful shipping box.

- Roadside recyclable

- Custom sizing

- FSC certified

- 3 colour printing

From £0.11 / unit

Have questions? Contact us

Key features

Specification

- F0

FEFCO 0933

FEFCO 0933 dividers are the most common form of interior fitting within a shipping box. These dividers have two lengthways and three widthways panels that slot together to form a lattice structure. Used mostly for transporting bottles or other items that need to be separated in transit. - Cd

Custom design

Partner with in-house packaging experts team to design a bespoke solution together. Bespoke packaging often results in a more precise product fit, which reduces costs and minimises waste. - Bk

Brown kraft liner

FSC certified, unbleached and uncoated liner paper made from virgin pulp. Brown kraft liner balances sustainability with good print performance. We recommend this kraft liner if you want to print on a brown divider. Colours may appear slightly muted because of this kraft liner's brown colour. - Wk

White kraft liner

FSC certified, bleached liner paper made from virgin pulp. White kraft liner is the best option for printing bold colours and flood coating. We recommend this kraft liner if you want to print on a white divider. - Bt

Brown testliner

FSC certified paper made from 100% recycled fibres, brown testliner is a cost-effective paper used on most non-printed dividers. We recommend this liner paper if you’re not printing on your divider. This reduces the carbon footprint and cost of your packaging. - Wt

White testliner

FSC certified and made from 100% recycled fibres, white testliner is a cost-effective paper used on white non-printed dividers. We recommend this liner paper if you’re not printing on your divider. This reduces the carbon footprint and cost of your packaging. - B

B-flute

B-flute (2.5-3.5mm) is the most common fluting for box dividers. It has good crush resistance and its thickness offers extra cushioning. A high number of flutes per foot also creates a smooth surface for printing on. B-flute is the most sustainable and cost-effective fluting option. We recommend this fluting unless your product needs extra protection. - Wi

Water-based inks

Made with water as their primary base, these inks are designed for flexographic printing. More sustainable than solvent-based inks.

Supply chain assurance

A resilient, responsible supply chain