Fully customisable

FSC certified

5 size options

Crash Lock Mailer Box

Minimum order quantity: 5000

Crash lock boxes are one of the quickest types of packaging to assemble. This makes them ideal for packing high volumes by hand and rapid fulfilment, saving time and reducing costs in the process. Often used by e-commerce stores as an alternative to a mailer box.

- Made for e-Commerce

- FSC certified

- Flexographic printing

- Rapid fulfilment

- 5 sizes

Have questions? Contact us

Key features

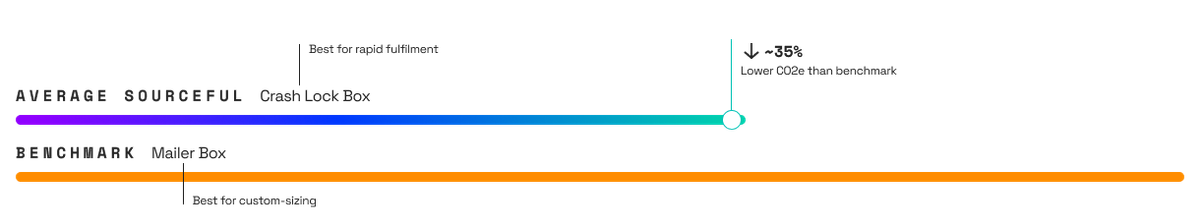

Carbon footprint

Switch to a Crash Lock Mailer Box and reduce your carbon footprint by up to 35%.

How is this calculated?

Specification

- F0

FEFCO 0713

FEFCO 0713 is a pre-glued box made from one piece of board which is commonly used to improve packing efficiency. Shipped flat and ready to use on arrival. - Bk

Brown kraft liner

FSC certified, unbleached and uncoated liner paper made from virgin pulp. Brown kraft liner is a sustainable material that still provides high print performance. - Wk

White kraft liner

FSC certified, bleached liner paper made from virgin pulp. White kraft liner is a good option for printing bold colours without choosing a coated paper. - Wc

White coated

FSC certified, bleached paper made from recycled and virgin pulp. Coated with kaolin clay to create a smooth surface for printing with a shine.. - Bt

Brown testliner

FSC certified paper made from 100% recycled fibres, brown testliner is a cost-effective paper often used on non-printed boxes. Testliner can be printed on but we recommend kraft liners for the best print performance. - Wt

White testliner

FSC certified paper made from 100% recycled fibres, white testliner is a cost-effective paper. It's used on non-printed sides of certain crash lock mailers, which reduces the carbon footprint and cost of your box. We don’t recommend this paper for printing.

Supply chain assurance

A resilient, responsible supply chain