Fully customisable

FSC certified

Custom sizing

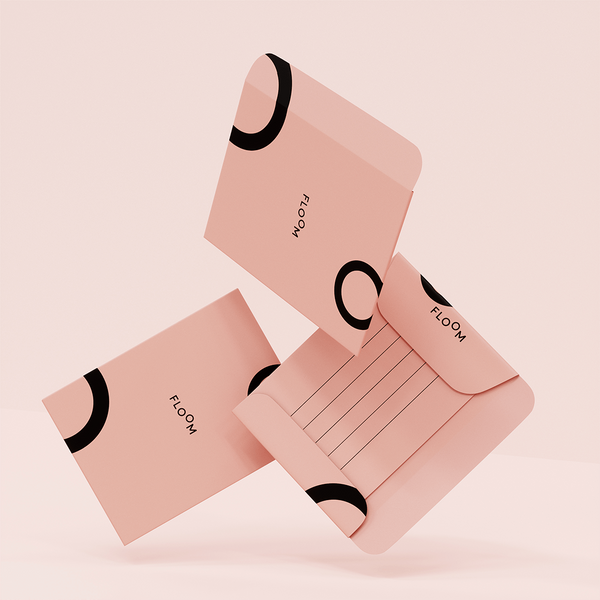

Custom Envelopes

Minimum order quantity: 1000

Envelopes are ideal for sending marketing materials, return slips, product information and more. Choose between stock sizes or create a custom size, and brand on both sides with your logo or artwork.

- Custom printing

- Digital Print Full Colour CMYK

- Double-sided printing

From £0.03 / unit

Have questions? Contact us

Key features

Specification

- Sf

Straight flap

An envelope with a rectangular flap. Due to the large glue area, straight flap envelopes are a secure way to send heavier items. - V

V-flap

An envelope with a triangular flap. The v-shaped flap gives the envelope an elegant finish whilst also securing what’s inside. Ideal for greeting cards or marketing materials. - G

Gummed

Gummed adhesive requires activation by water contact. Before activation gummed adhesive is not sticky making the envelopes easy to transport and store. To use gummed adhesive, simply activate with water and fold the flap of the envelope down to secure it. - Ps

Pressure sensitive adhesive

Commonly used on envelopes packed by a machine. The pressure sensitive adhesive does not need water or heat to activate. To seal, simply fold the flap down. - Sp

Single peel & seal

One strip of adhesive covered with a fibre-based backing paper. To seal an envelope with single peel & seal, simply remove the backing paper and fold down the flap. - Dp

Double peel & seal

Two strips of adhesive covered with fibre-based backing paper. A double peel & seal makes returns easy for your customers. We recommend a double peel & seal for larger envelopes. - Ss

Standard sizes

Standard envelope sizes are useful for pairing with cards and are suitable for most needs. - Cs

Custom sizing

Choose any height and width within the minimum and maximum size range. Custom sizing is great for creating bespoke envelopes, and you can pair them with a custom-sized card. Minimum size: 140x140mm, maximum size: 680x478 - Wp

White paper

FSC certified, bleached paper is made from virgin pulp. White paper is the best choice for printing bold, bright designs or flood printing. - Bp

Brown paper

FSC certified, unbleached paper made from virgin pulp. Brown paper is more sustainable than white paper as it doesn’t involve the bleaching process. Colours may appear slightly muted because of its brown colour. - Wr

White recycled paper

FSC certified, this bleached recycled paper is made from recycled paper pulp. It’s more sustainable than using virgin materials but is often more expensive. - Br

Brown recycled paper

FSC certified, this paper is made from recycled paper pulp. It’s more sustainable than using virgin materials but is often more expensive. - 1

100gsm

One of the most common envelope thicknesses. 100gsm (standard) envelopes are durable and cost-effective, suitable for shipping documents or smaller brochures. - 1

150gsm

A thicker paper stock, 150gsm (premium) envelopes create a more premium feel as well as offering more protection. Ideal for shipping heavier items. - 2

200gsm

The thickest and most durable option. 200gsm (luxury) paper is stiffer than other options so we don’t recommend choosing it for smaller envelope sizes. - Wv

Water-based varnish

Protects your envelopes from rain and spillages but doesn't make them waterproof. It also prevents the envelope’s colour from fading. A water-based varnish doesn't affect recyclability. - Su

Spot UV varnish

Spot UV is a varnish applied to specific areas of a design. Can be applied on top of a printed area or straight on the paper itself. Ideal for highlighting important design elements such as logos and text. - Pt

Print toner

Used for digital printing. - Si

Soy-based inks

Made with soy as their primary base, these inks are designed for offset printing. More sustainable than solvent-based inks. - Ui

UV inks

UV ink is a fast-drying alternative to solvent-based inks. UV ink can be printed on a wide range of materials and creates a vibrant finish. Used in combination with offset printing.

Supply chain assurance

A resilient, responsible supply chain